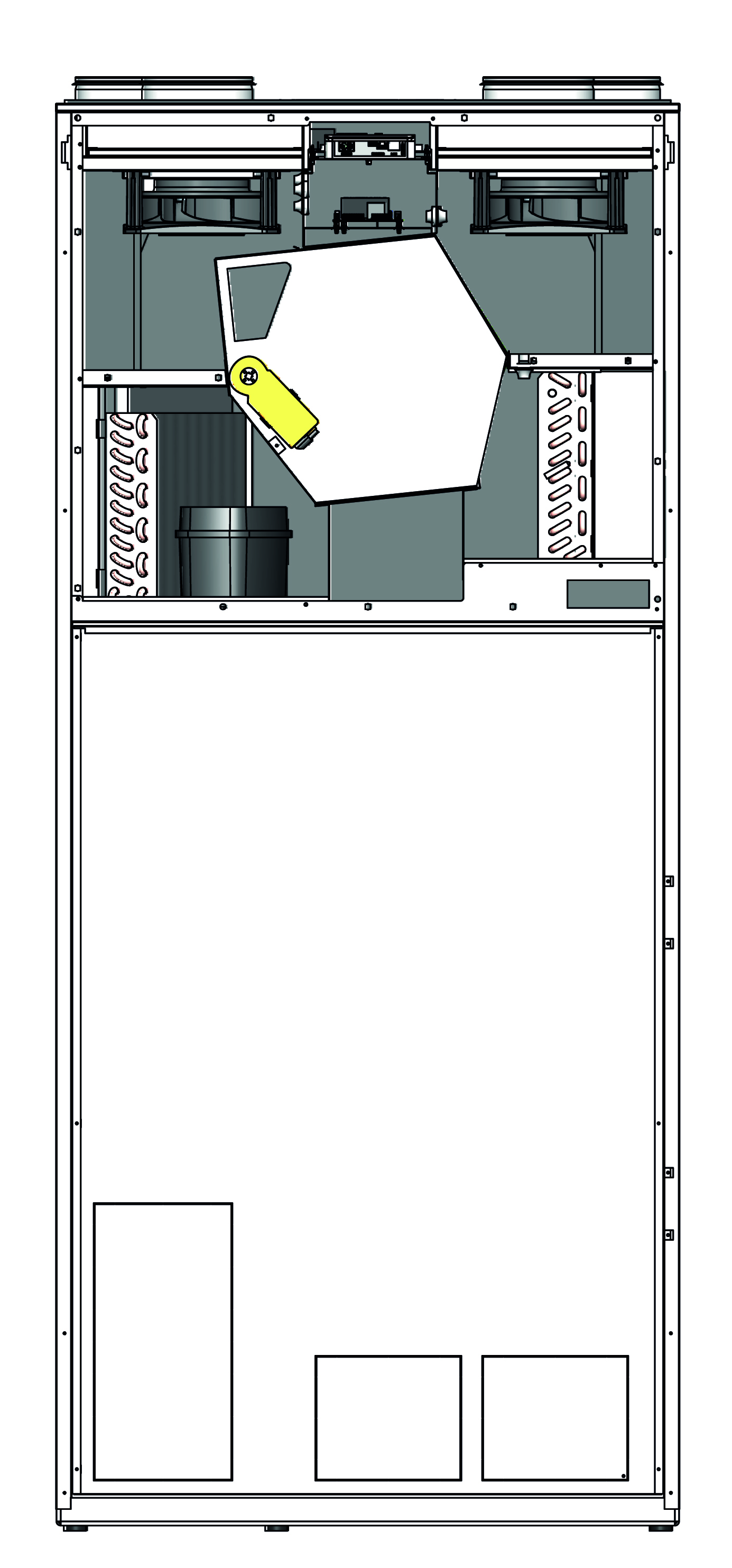

Compact P2 EK

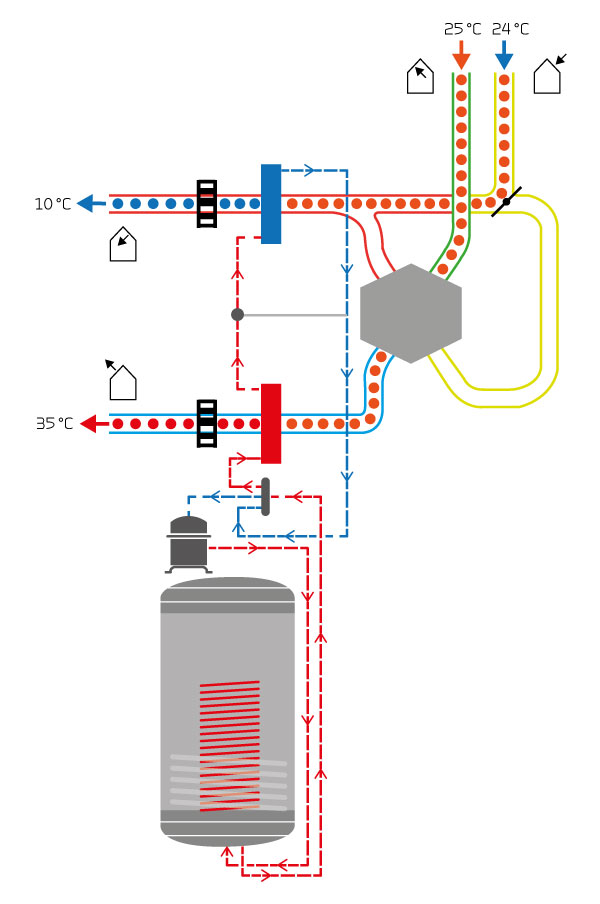

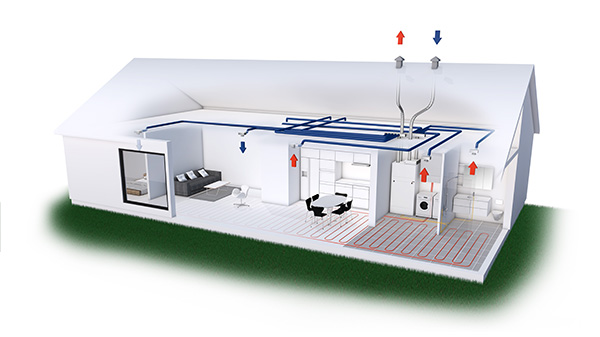

Compact P2 EK is a multi-unit with three installations combined in one compact installation. It is intended for smaller dwellings with a ventilation requirement of up to 425 m3/h. The three installations comprise ventilation of the dwelling, production of domestic hot water, and electric heating of the dwelling.

By integrating all three installations in just one installation, you save considerable space in the machine room. Another advantage is that you avoid having to bury geothermal tubes and installing an air source heat pump. This is required with traditional heating solutions using a heat pump. Installation of Compact P2 EK is therefore easier and cheaper.

Electric heating is a good solution if the dwelling is highly air tight, as is the case in e.g. Passive Houses. They use limited energy on heating. However, you need to ensure that legislation allows electric heating.

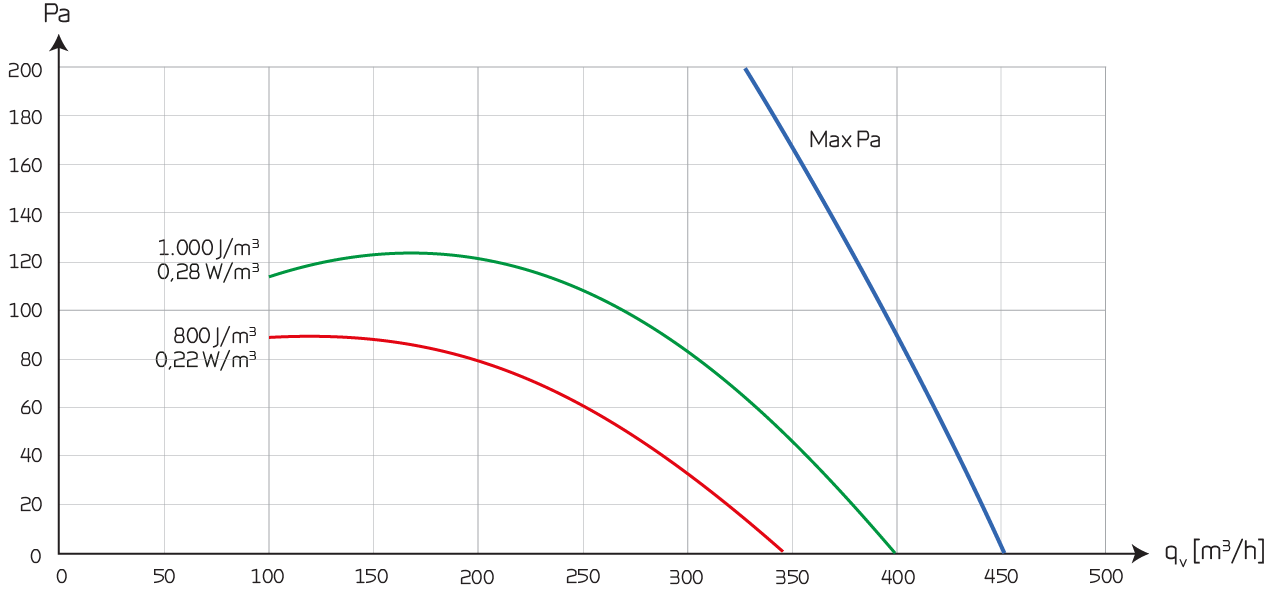

Airflow (see planning data for SEL/SFP values)

Min : 100 m3/hMax : 425 m3/h

The “heart and lungs” of the house

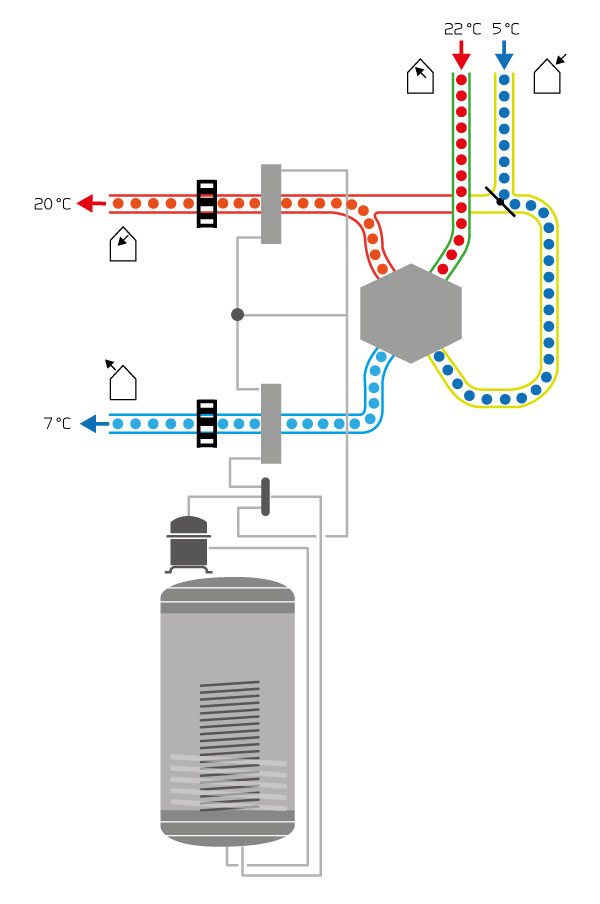

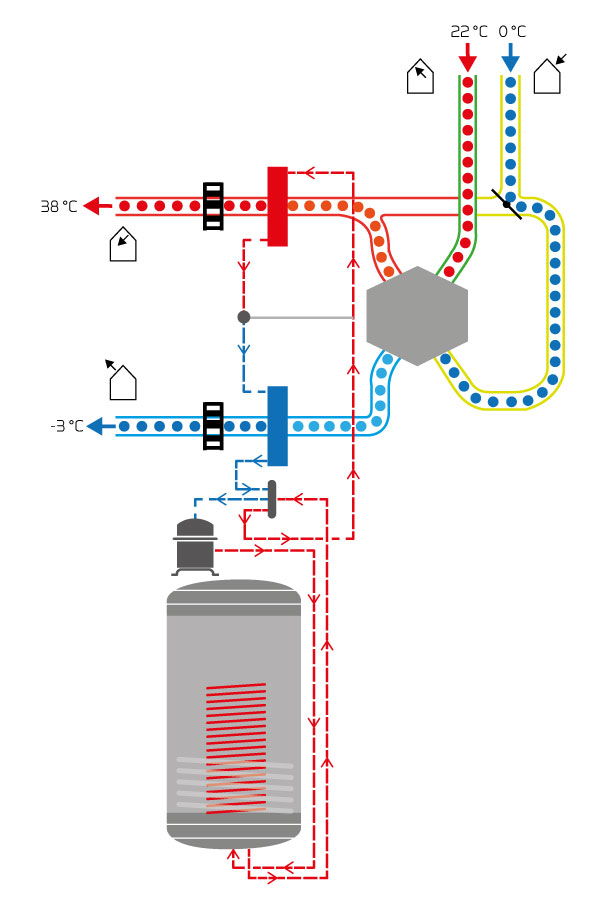

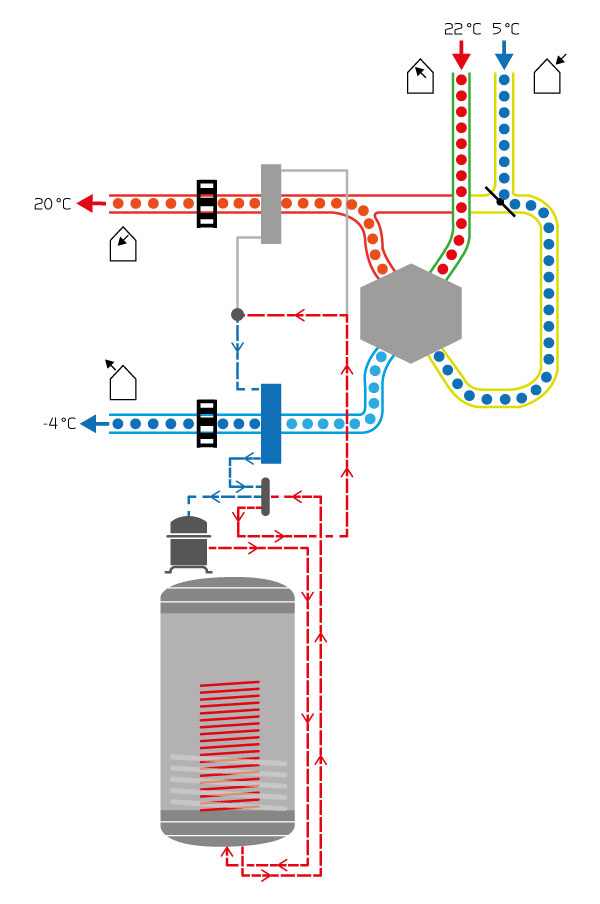

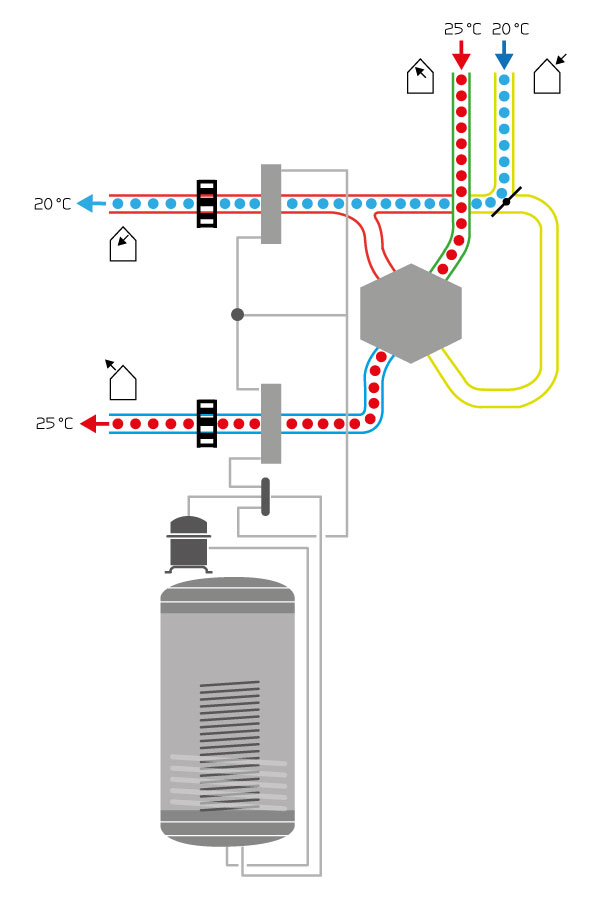

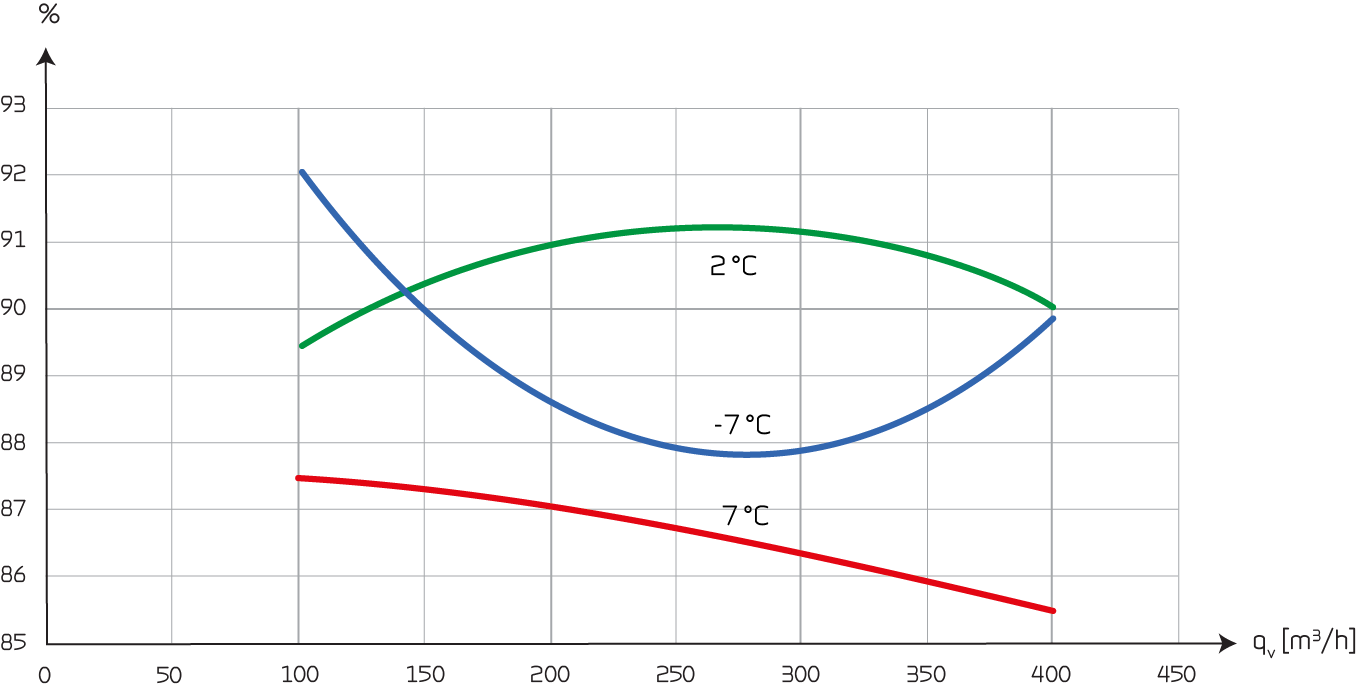

Compact P2 is not a traditional ventilation unit. In contrast to other ventilation units, it recovers 100% of the heat from the extract air. The counterflow heat exchanger makes it possible to recover up to 95% of the energy in the extract air. This is then used to heat the outdoor air. The integral heat pump will utilise any remaining energy for producing domestic hot water.

Compact P2 EK has an integral electric boiler that can be connected up to a hydronic central heating system and thereby heat the dwelling using electricity.

Compact P2

EK 3 kW (Electric boiler)

EK 6 kW (Electric boiler)

EK 9 kW (Electric boiler)

|

CapacityCapacity of standard unit as a function of qv and Pt, ext SEL values according to EN 13141-7 are for standard units with ISO 16890 Coarse 75% (G4) filters and without heating element. SEL values comprise the unit’s total power comsumption excl. control. Conversion factor: J/m3 : 3600 = W/m3/h. NB! The SEL values are measured and stated as a total value for both fans. |

|

Temperature efficiencyTemperature efficiency as a function of volume flow qv [m3/h] for unit with counterflow heat exchanger. Temperature efficiency according to EN13141-7 (2°C / 20°C). NB! The temperature efficiency, is for the heat exchanger only (without heat pump operation). |

|

|

|

|

|

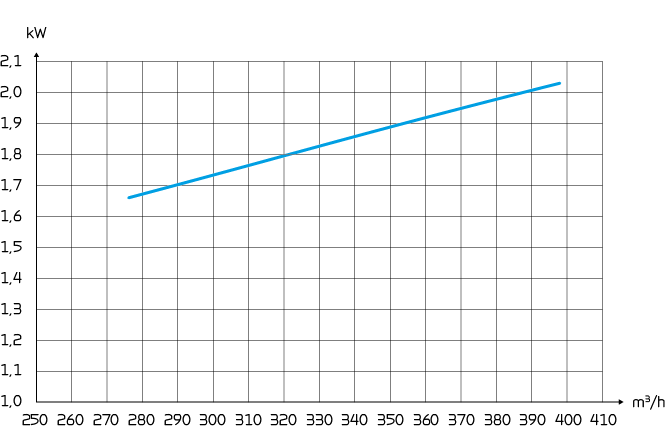

Cooling effectCooling effect Q [kW] as a function of volume flow [m3/h] according to EN14511, extract air = 27 °C, outdoor air = 35°C. The cooling effect is the contribution added to the fresh air via the Compact P2 to the supply air. |

|

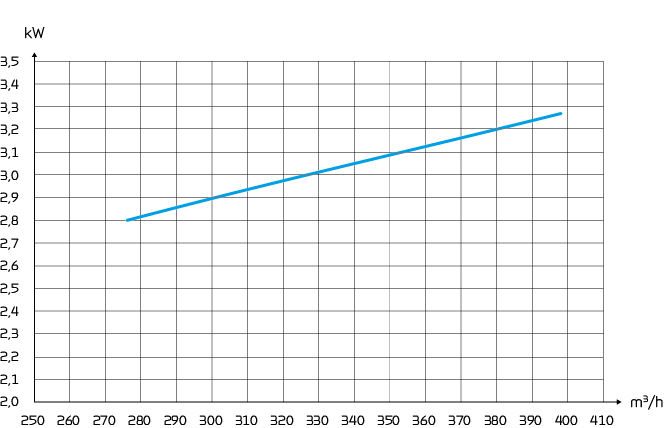

Energy efficiency ratioEnergy efficiency ratio EER [-] for supply air as a function of volume flow [m3/h] acc. to EN 14511 at extract air temp. = 27 °C and outdoor air temp. = 35 °C. NB! COP according to EN 14511 is calculated for the heat pump and counter flow heat exchanger combined. |

|

Sound dataSounddata is for qv = 275 m3/h and Pt ext = 100 Pa in accordance with EN ISO 3744 for surface and EN 5136 for ducts. Sound output level LWA drops with falling air volumes and falling back-pressure. At a given distance, the sound pressure level LpA will depend on the acoustic conditions at the installation site.

|

|

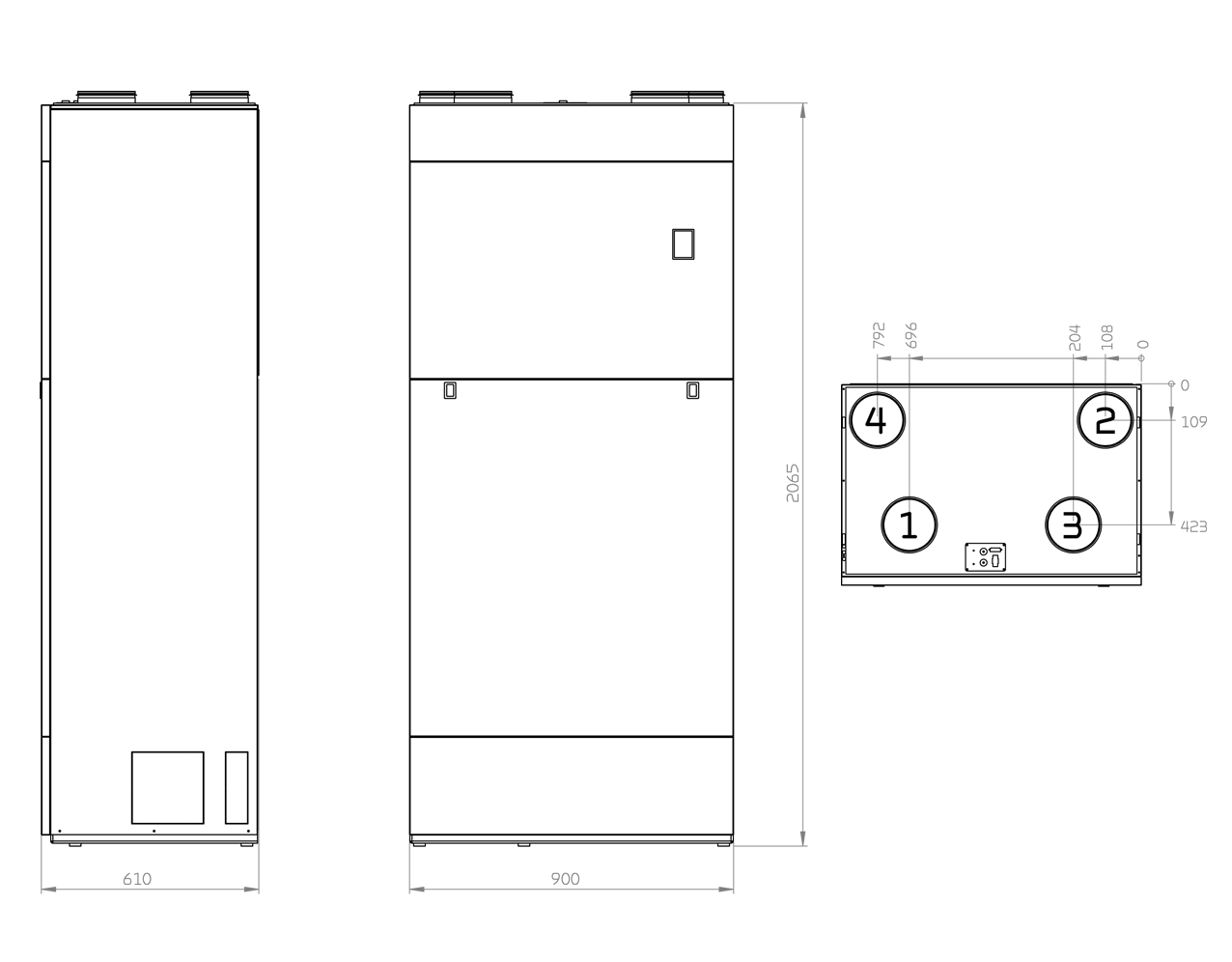

You can download AutoCad or Revit drawings with BIM data on several Nilan ventilation and heat pump solutions - the list is constantly being expanded. Click here to get more about BIM data on Nilan units

All dimensions are in mm. Connections: |

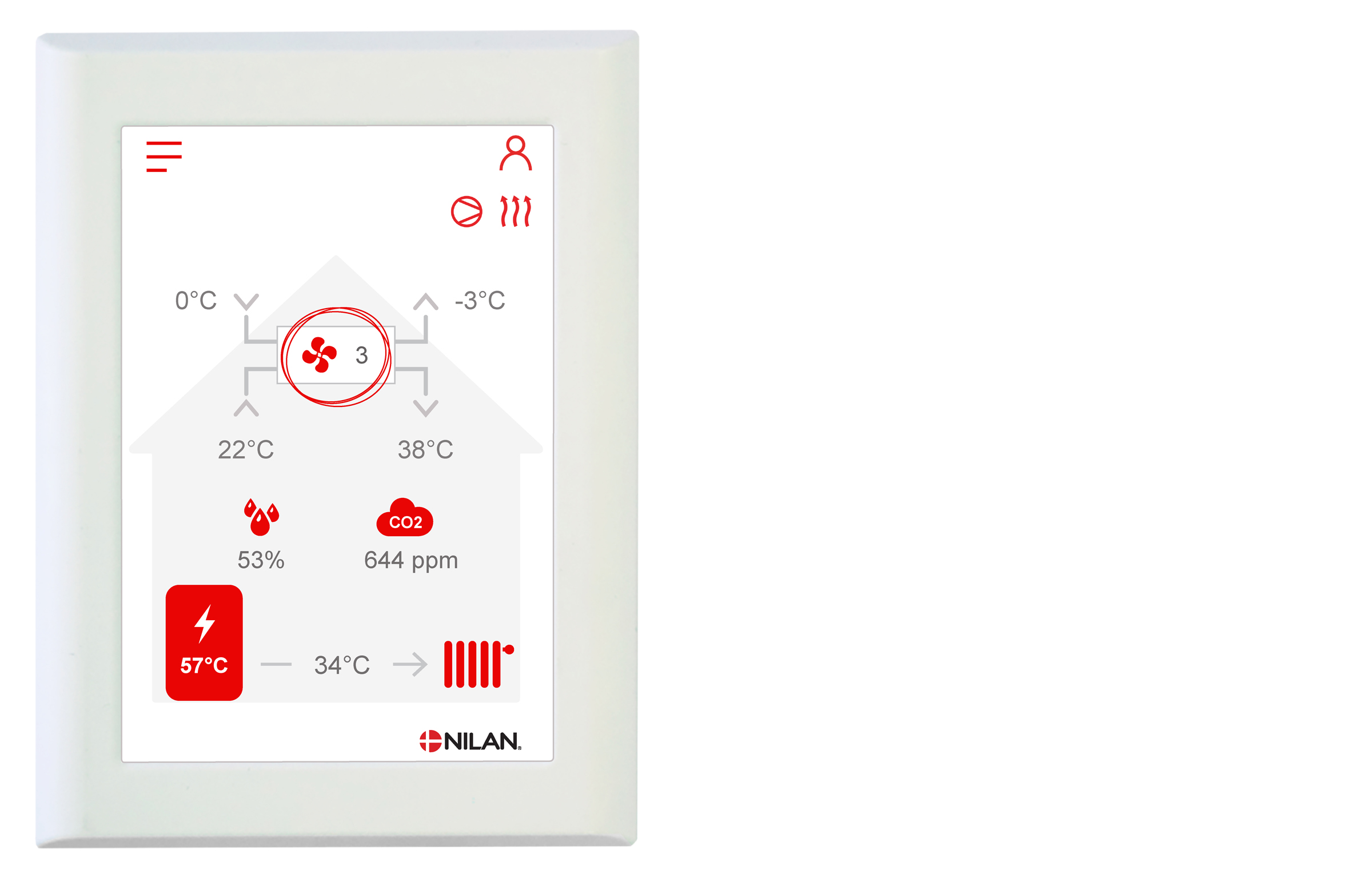

The CTS602 control system is an advanced control system with many settings options. The control system is supplied with factory default settings that can be adapted to the operational requirements in order to achieve best possible operation and utilisation of the unit. The HMI Touch panel provides an overview of the current operation of the unit. The structure of its menu makes it easy to navigate for both user and installer. You can choose from 2 different images for the main screen. External communication

You can find further information about all the functions in the Software and Installation instructions for the unit.

|

ATTENTION! When positioning the unit, you should always consider future services and maintenance. It is recommended that you leave a minimum of 60 cm of clear space in front of the unit. It must be easy to replace filters and it must be possible to replace, for instance, fans and other components. ATTENTION! The unit must be level to enable proper drainage from the condensate tray.

|

PHI certificate

The Compact P2 is certified by the German Passivhaus Institute, confirming that the unit meets strict requirements for energy efficiency and performance in low-energy buildings.

|